Sustainable Hot Water & Heating Products For Higher Education

Sustainable Hot Water & Heating Products For Higher Education

Design, Supply and Support for Hot Water & Heating for Colleges & Universities. Also available for Schools, Academies & Nurseries.

AIR SOURCE HEAT PUMPS

More informationSOLAR THERMAL PRODUCTS

More informtationHEAT RECOVERY UNIT

More informationPACKED PLANT ROOMS

More informationAdveco Supports:

- Sustainability as a core purpose of higher education

- The improvement, and better management of living and study spaces

- Working together to make sustainability ‘front and centre’ in the sector through site assessment programmes, bespoke application design and staff training

- Driving student engagement in sustainability through exemplar project delivery

Addressing efficiency of hot water and heating systems not only helps higher education meet sustainability goals in a practical and cost effective manner, it also delivers improved conditions for staff and the student body, providing access to better living and study spaces.

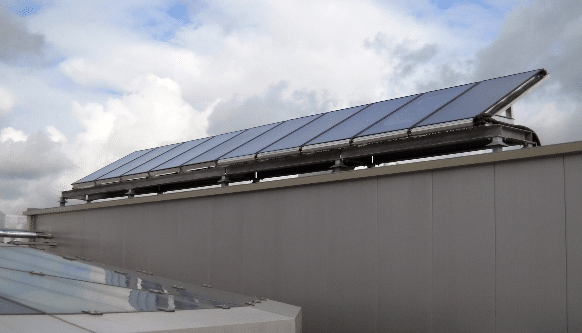

Solar Thermal system supplied by Adveco for Bolton College.

Live Metering – The most cost-effective and efficient path to sustainability for your school's future.

If you need assistance with a system for your school or nursery, then Adveco’s Live Metering service is for you. Live Metering requires an Adveco engineer to visit your site and install a water meter to provide hot water temperature monitoring for verified water data and comment on the risk of the existing system.

Adveco will return within the month to collect the meter. During these visits we can confirm space and clearances, and installation suitability, and once we have analysed the data give a truly accurate sizing and emissions/costs calculation.

- Quick, non-evasive temporary installation

- Visual site assessment & reporting by Adveco engineer

- Consistent 6 minute data 24 hours per day on existing hot water systems

- 50% of monitoring fee deducted if system recommendation purchased from Adveco

- Bespoke theoretical hot water modelling optimised to work with a building’s existing electrical supply

- Daily & annual hot water demands

- Annual estimated energy consumption

- Annual estimated carbon emissions

- Annual estimated operational costs

Adveco can then advise on a new hot water system which meets the demands of a building while increasing efficiency, lowering carbon emissions, and managing costs.

Heat Pumps For Colleges & Universities

For new buildings across the campus that are serviced by electricity only, the deployment of air source heat pumps (ASHP) as a method of pre-heating water represent a clear opportunity to introduce low carbon technology to meet sustainability goals.

University L70

Solar Thermal for Colleges & Universities

A proven and extremely reliable technology, solar thermal offers a clear path to reducing CO₂ emissions.

Correctly designed and sized to the application, such as student accommodation, solar thermal systems can generate a considerable proportion of the hot water requirements for buildings that are already on-gas with relatively short payback periods on the initial capital expenditure, while leveraging lower-cost gas to meet peak demands.

Solar Thermal system is supplied by Adveco for Bolton College.

Sustainable Hot Water & Heating For Higher Education

Establishing a culture of sustainability across higher education estates and embedding climate action priorities into strategic plans are now core objectives within universities and colleges across the UK.

In the 2018/19 academic year, UK universities emitted approximately 1.7 million metric tonnes of CO₂ equivalent emissions, making up 0.5% of the UK’s total emissions. In response, higher education providers have made a collective effort to improve sustainability across the sector, with universities declaring climate emergencies and making commitments to create sustainable campuses and achieve net-zero emissions. In October 2021, 140 members of the COP26 Universities Network backed a new set of commitments on climate action to support targets for reducing carbon emissions by 78% by 2035.

Delivering green estate management policies to support net zero targets with the aim of transitioning to new ways of operating buildings or developing new, more environmentally friendly buildings or full estates are the foundation for reducing carbon footprints.

Fusion Packaged Electric Water Heaters

Reduce carbon emissions by up to 70% with compact, resilient & easy-to-install packaged commercial electric water heaters

Ardent Commercial Electric Boiler

Compact and reliable 9-100 kW electric boilers for seamless, low-carbon hot water in commercial spaces.

Solar Collectors with Drain Back

Cuts carbon emissions and offsets operating costs associated with commercial water heating

FPi32 Air Source Heat Pumps

Reduce water heating carbon emissions year round with a compact 9 kW or 13 kW monobloc Air Source Heat Pumps

Want to find out more?

Higher Education Brochure