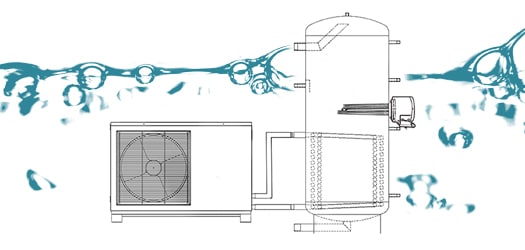

Hybrid Hot Water Systems for Lower Carbon

The drive to bring greater sustainability into commercial and public sector buildings has never been more urgent, yet the consistent need for heat, in particular, to meet hot water demands cannot be avoided. Reducing carbon from what is typically classed as a business-critical service, especially in the wake of COVID and the drive to enhance … Read more