Ensuring Hot Water Flows: Resilience & System Redundancy

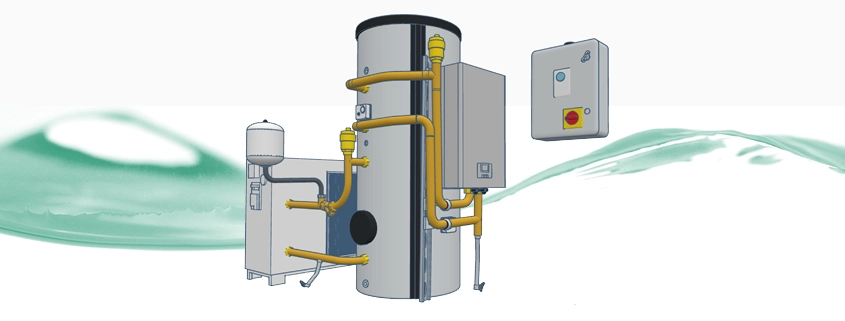

Adveco looks at new ways to approach hot water system redundancy in the modern commercial landscape and why it matters… Reliable access to hot water is often a business-critical service, often as important as electricity or internet connectivity. System downtime can be extremely risky for organisations, and depending on the industry, hot water outages can … Read more