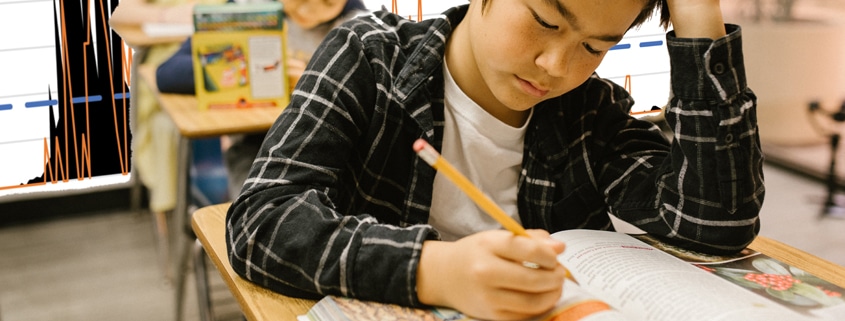

Solar Thermal For Education Buildings

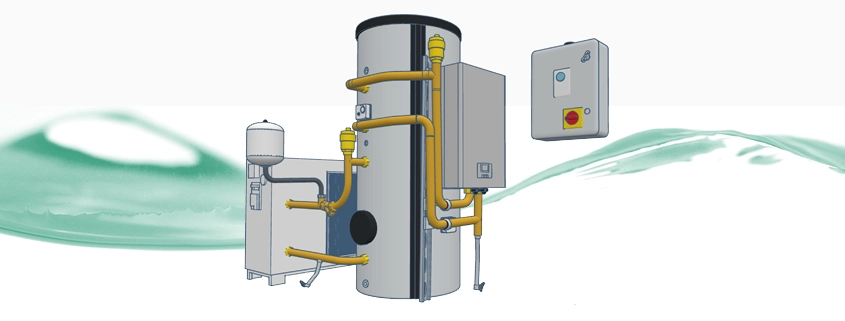

As the education sector is challenged to reduce energy demands to cut carbon emissions as well as trying to balance climbing operating costs, Adveco considers the advantages of adopting solar thermal for educational buildings as a means to meet more sustainable and cost-effective hot water requirements. Capable of offsetting typically around 30% of the energy … Read more